Test Kit Assembly And Testing Bench

production stage 1

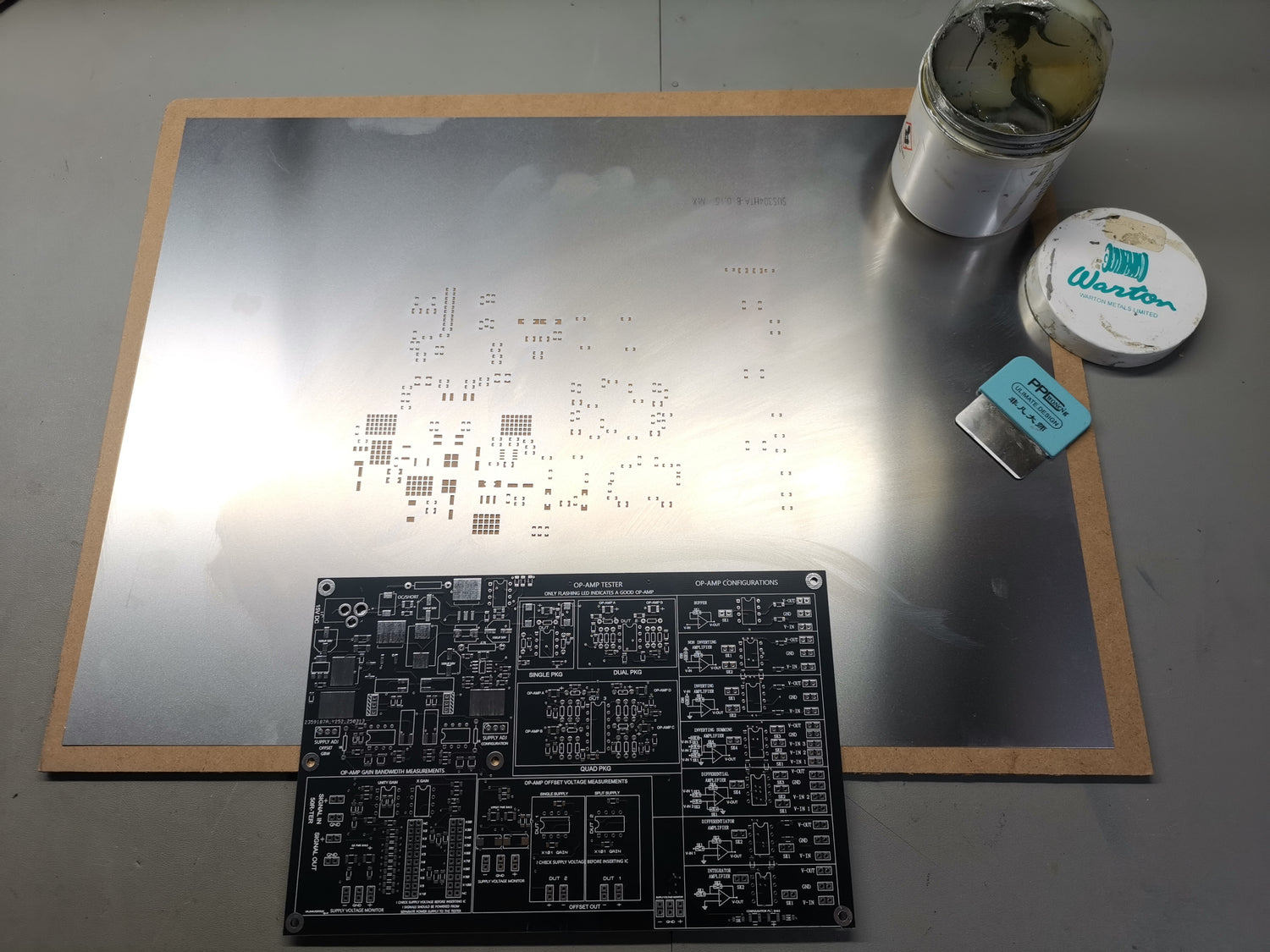

Solder Paste Application

Solder paste application involves using a stencil to deposit paste onto a PCB's pads, allowing for the quick and precise placement of surface mount devices (SMDs)

production stage 2

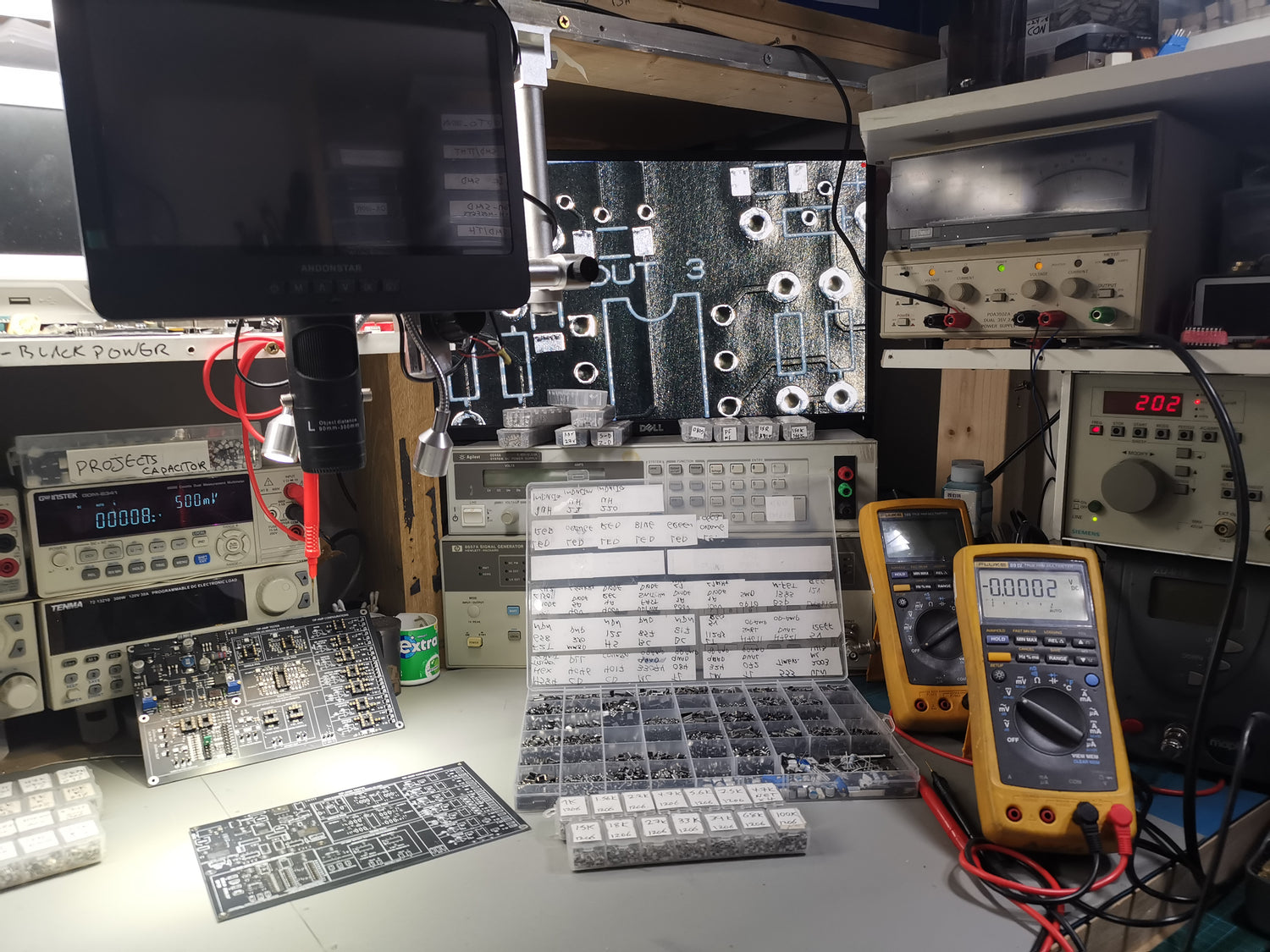

Component Placement

Using magnifying microscope SMD parts are placed on bare PCB ready for reflow.

production stage 3

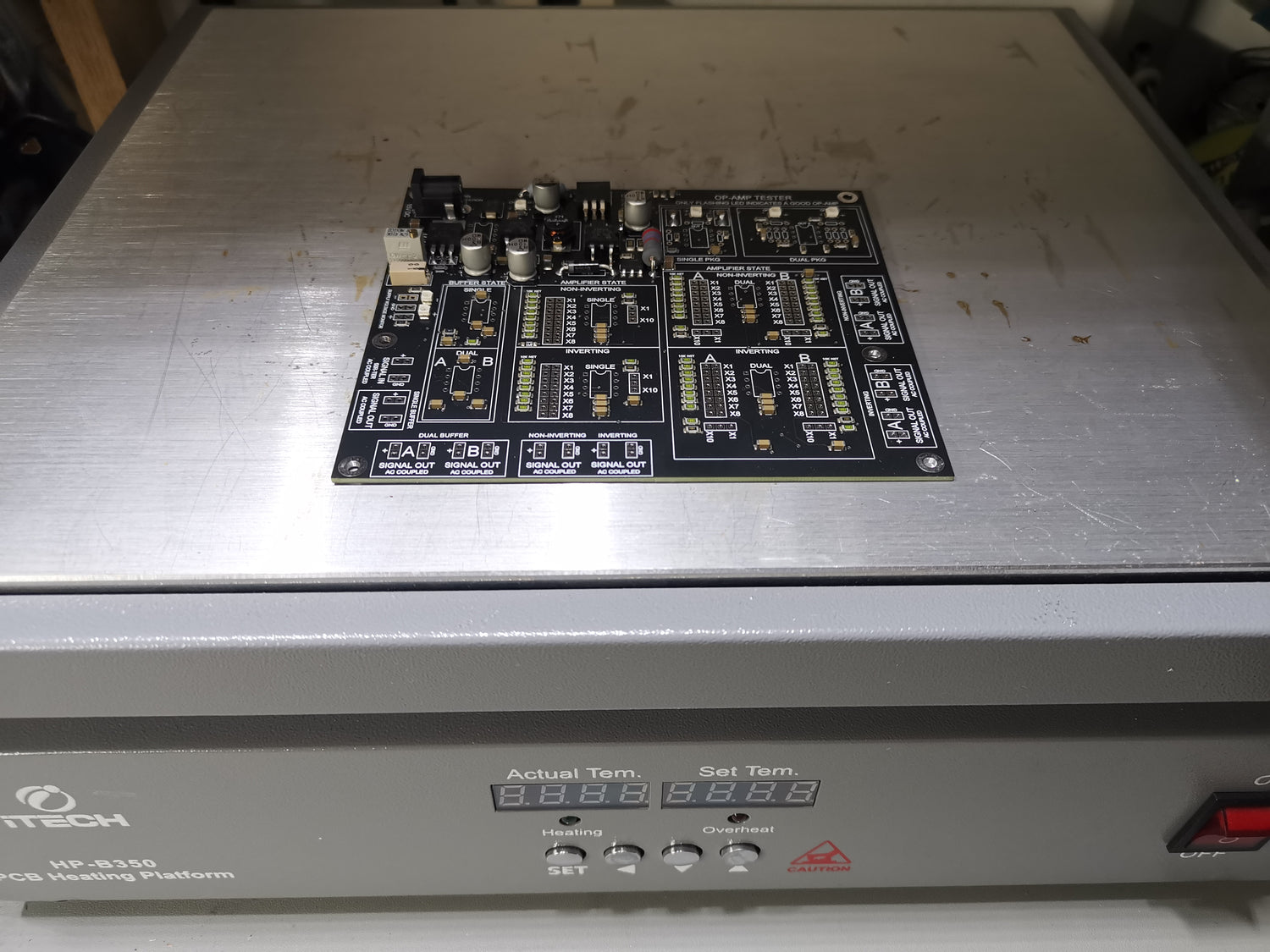

Solder Reflow

Using a reflow plate to heat the PCB and allow the solder paste to melt and reflow and bond the SMD parts to PCB. Once this procedure is complete , Boards are naturally cooled and visually checked to make sure components are reflow correctly and all joints are solid.